Get in touch

555-555-5555

mymail@mailservice.com

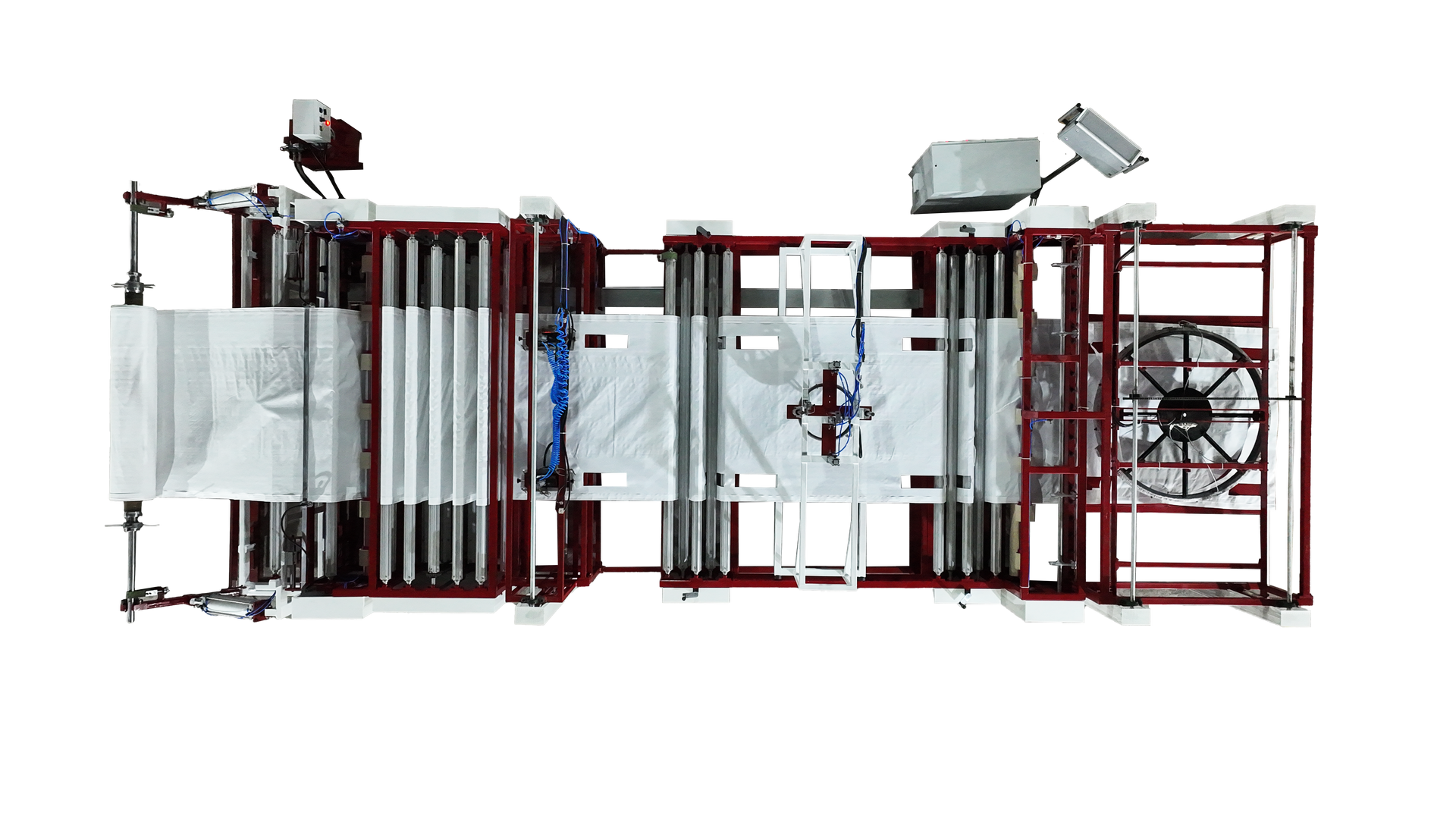

FABRIC CUTTING MACHINE

Model 1

PP WOVEN FABRIC CUTTING MACHINE FOR FIBC INDUSTRY

Model: FabTek

Brand: ARMSTRONG

Armstrong is a leading manufacturer of FIBC fabric cutting machines for jumbo bags and woven sacks. Our machines are designed to provide fast and efficient cutting, resulting in better finishing and lower labour costs.

We manufacture Fabric cutting machines for FIBC jumbo bags and for woven sacks. The fabric cutting machine is ideal for fast and proficient cutting, better finishing, and helps save labor costs.

Fabric Cutting Machine for FIBC Jumbo Bags:

The FIBC fabric cutting machine makes fabric cutting easier and supports two types of cutting:

1. Heat cut: Heat-cut fabric cutting for precise production is the best choice.

2. Ultrasonic cut: Ultrasonic fabric cutting for food-grade production is the best choice.

Model 2

FIBC FABRIC CUTTING MACHINE (WITH BIG SPOUT)

PP WOVEN FABRIC CUTTING MACHINE FOR FIBC AND WOVEN SACK INDUSTRY

Model: FabTek (2200MM WIDTH SIZE)

Brand: ARMSTRONG

The FIBC manufacturing process amplifies the chances of mistakes in manual fabric cutting with surmount time consumption. The Automatic fabric cutting machine makes it all easy and is worth introducing to the marketplace. An intellectual integration with spout diameter punching is the idea to separate diameter punching for any kind of FIBC or Jumbo Bags..

Thi fabric cutting machine is customised to make Circular bulk bags (FIBC) have a circular/tubular body that is seamless. With only a top and bottom panel sewn into the bag, circular style bags are ideal for fine and hygroscopic materials.

These Bulk Bags/ FIBC Bags are made from circular/ tubular woven fabric on looms. The circular fabric is with a reinforcement panel on the body of the fabric. These bags are with cross corner loop attachment and the loops are attached on the reinforcement panel on the fabric. The normal width of these bags is 180 cms double lay flat (tubular) but we can provide circular bags with max width of 210 cms, double lay flat. These bags can be supplied in various filling and discharge options for various duty conditions.

There is management with a microprocessor controller to keep all important data such as total cutting meters orders wise.

Type of Cutting:

1. Heat cut: Heat cut fabric cutting for precise production is the best choice.

2. Ultrasonic cut: Ultrasonic fabric cutting for food-grade production is the best choice.

We also offer side folding system as per customers demand. This attachment makes thing easy for the FIBC bag manufacturers.

Our Machine is reliable and efficient to cut accurate panels as per customers’ requirement. Be in spout cutting or X or V or I cutting - we provide a complete solution when it comes to PP Fabric cutting. Fabric pieces of up to 25 Mtr lengths can be cut for other applications as well. The machine is equipped with servo motor that helps in achieving the cutting length of 1 mm. Further, these woven sack fabric cutting machines features alloy steel cutter and web guide system to achieve high precision in involved PP/HDPE fabric cutting operations. Some of the optional equipment we can offer these with includes Zig-zag cutter and printing mark reading sensor. We provide various models but mainly 1400mm and 2200mm fabric width cutting is widely used.

The one and only complete solution providers of high-quality industrial finishing machines and spare parts.

079-27543747 | +91 63587 40011/16

info@armstrongex.com

Address

OFFICE

501, ‘Sarap’, Opposite Navjivan Press

Ahmedabad, GJ - 380014, India

FACTORY

Plot no. A2/502-1,

Opp. Indo-German Tool Room

Phase - 4, GIDC Estate

Vatva, Ahmedabad, GJ - 382445, India