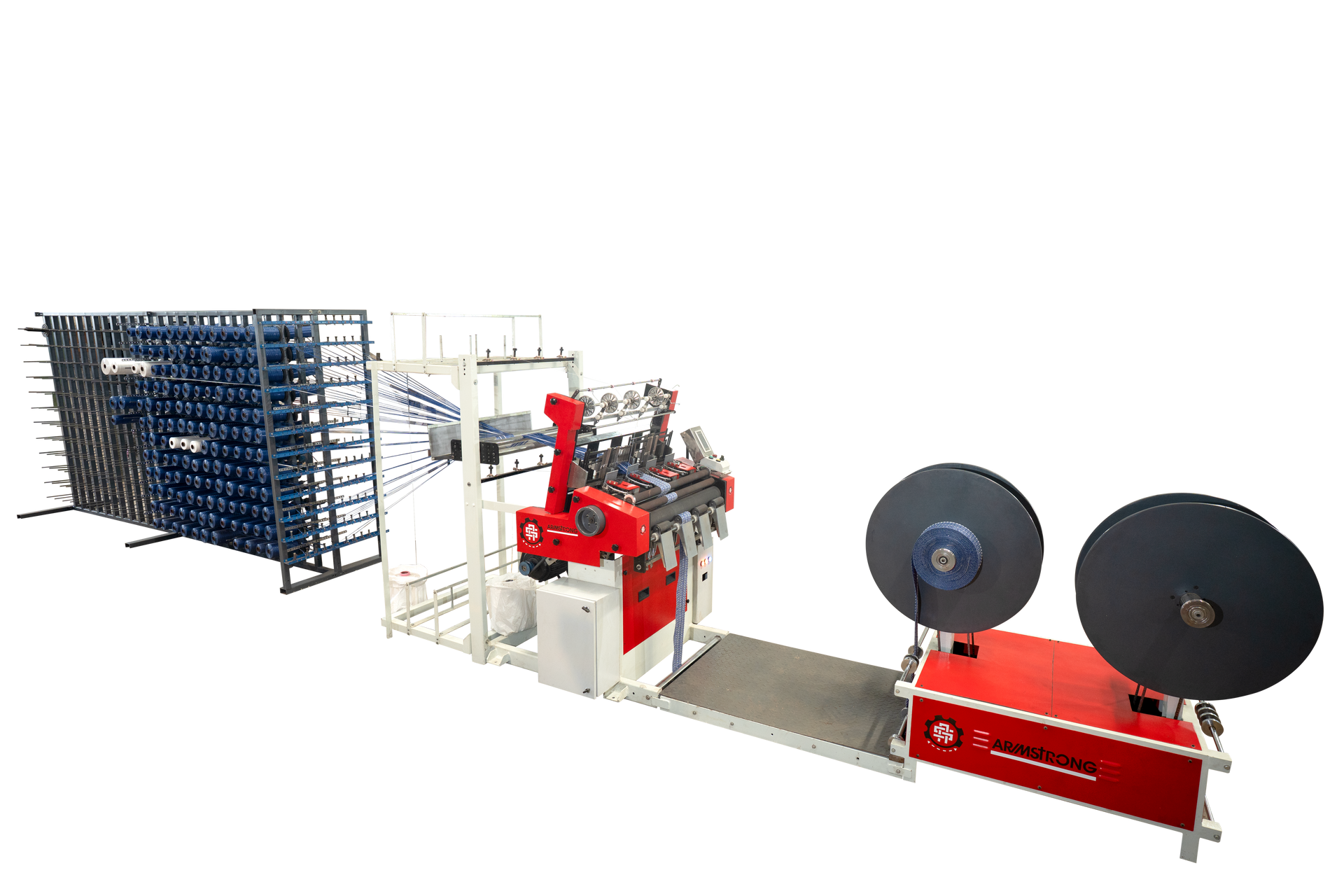

NEEDLE LOOMS MACHINE (WITH HMI)

Ribbon Making Machine / Webbing Loom Machine

Model : N loomtek (4-100)

Make : ARMSTRONG

ARMSTRONG High-Speed Needle Loom Machine Model 4 x 100 is equipped with 4 tape heads, a reed width of 100 mm, and supports fabric thickness from 0.3 mm to 3 mm. It ensures high-speed, high-quality belt production with maximum efficiency.

The machine comes with a Smart Control Panel (PLC + HMI) that handles length counting, speed (MPM) display, and real-time fault alerts.

Built for strength, speed, and precision, the Armstrong Needle Loom Machine is the ultimate solution for manufacturing high-load webbing products like FIBC webbing slings, army and safety belts, cargo lifting straps, sofa elastic tapes, span polyester, and industrial belts.

Engineered to handle a variety of materials — PP flat film, cotton, nylon, and high-bulk polyester — this machine ensures consistent quality for even the most demanding applications.

Key Features:

Soft Start System for longer machine life

Heavy-duty main shaft support for stable, vibration-free performance

Smart PLC + HMI control panel for speed, length counting & fault alerts

Precision inching mode for accurate yarn alignment

HMI-controlled yarn break detection for quick response

Balanced load system with dual timing belts + V-belt

Quick CAM-based thread lock mechanism for easy maintenance

Durable alloy steel gears for long-term reliability

Speed control with optional 10–25% boost for lighter runs

Why Choose Armstrong?

Low power consumption for cost-efficient operations

Advanced automation for complete process control

Easy access to reliable, precision-made spare parts

Extended lifespan with up to 200% longer part durability