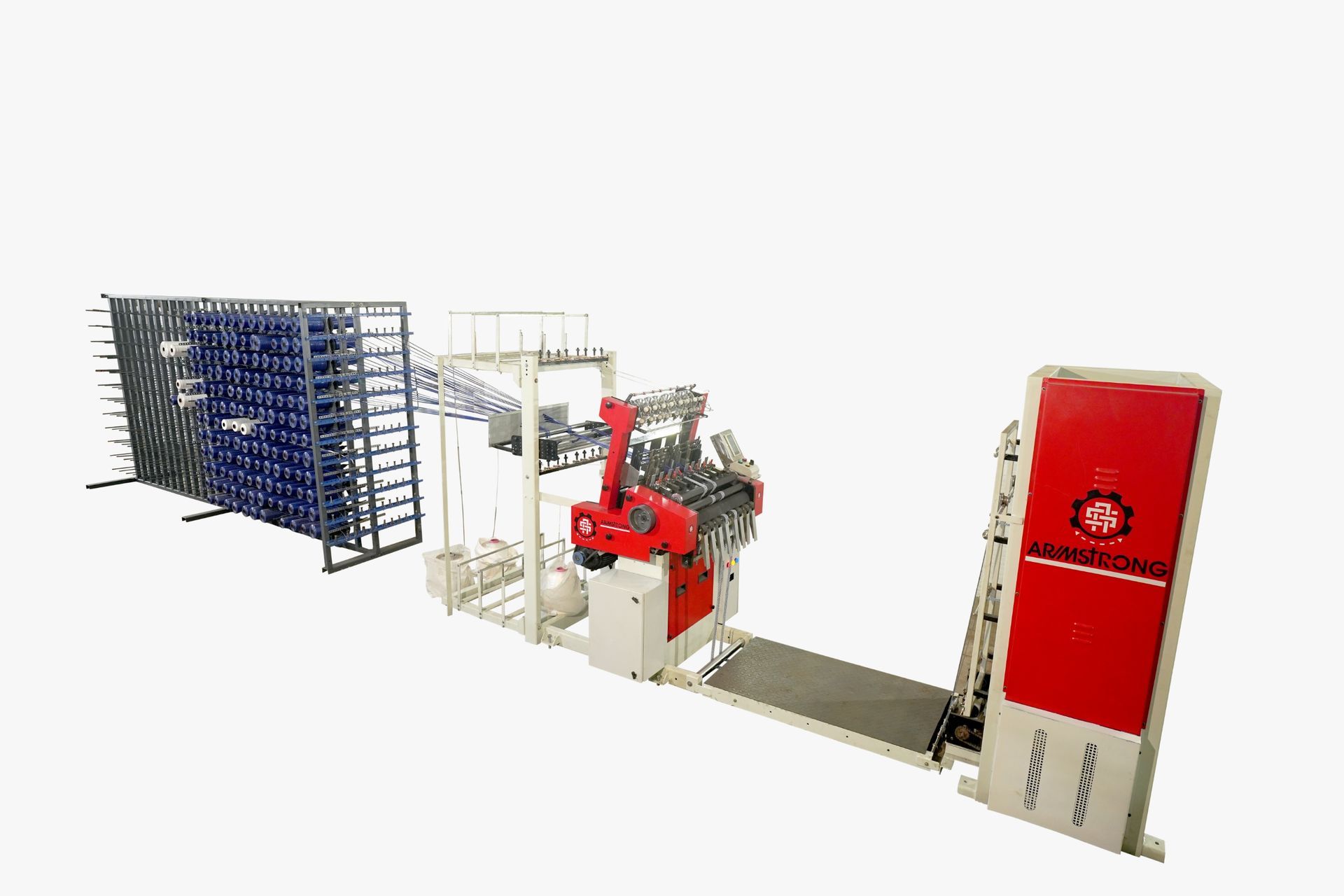

PP BELT WEAVING MACHINE / NEEDLE LOOM WITH HMI & PLC + VFD MACHINE

Model : NLoom Tek (8-30)

Brand : ARMSTRONG

ARMSTRONG High-Speed Needle Loom Machine Model 8 x 30 is equipped with 8 tape heads, a reed width of 30 mm,

and supports fabric thickness from 0.3 mm to 5 mm. It ensures high-speed, high-quality belt production with maximum

efficiency.

The machine comes with a Smart Control Panel (PLC + HMI) that handles length counting, speed (MPM) display, and

real-time fault alerts.

It supports a wide range of materials like PP flat film, cotton, nylon, and high-bulk polyester, making it perfect

for demanding, high-load webbing production.

Key Features That Deliver Performance

1. Soft Start System

Reduces stress on gears and moving parts, increasing machine longevity.

2. Sturdy Main Shaft Support

Heavy-duty one-side lock bearing ensures stable, vibration-free performance.

3. Smart Control Panel (PLC + HMI)

Handles length counting, speed (MPM) display, and real-time fault alerts.

4. Precision Inching Mode

Fine-tunes yarn alignment and improves setup accuracy.

5. HMI-Controlled Yarn Break Detection

Minimizes wiring and improves fault response speed.

6. Balanced Load System

Power is distributed via dual timing belts + one V-belt for smoother operation.

7. Quick Thread Lock Mechanism

CAM-based system simplifies maintenance and threading.

8. Durable Gear Construction

Made from hardened alloy steel for long-term performance.

9. Speed Control via HMI

Lock desired MPM to ensure steady and safe production.

10. Extra Output When Needed

Increase MPM by 10–25% for lighter tape runs.

Why Armstrong FIBC Needle Loom?

- Our Machine runs with lowest power consumption ever.

- Equipped with next generation easy operating HMI & PLC + VFD. For ensuring MPM , Desired length of Belt and if any Alarm like length finished , yarn cut , Main motor overload etc. Will show massage on display.

- All gears & parts are manufactured on automatic machinery for ensuring your after sales parts replacement.

- Smooth start of machine and inching for reducing starting torque is increasing moving parts life up 200%.