EXPERTS-LED

MANUFACTURERS & EXPORTERS

of comprehensive industrial solutions to HDPE / Woven Sack traders, since 1982.

Enquiry Form

Send us your details and we’ll get back to you to schedule a time to talk.

What we are providing

Latest FIBC & Woven Sack Industry Finishing Machinery, sewing machines, spares and effective industrial solutions.

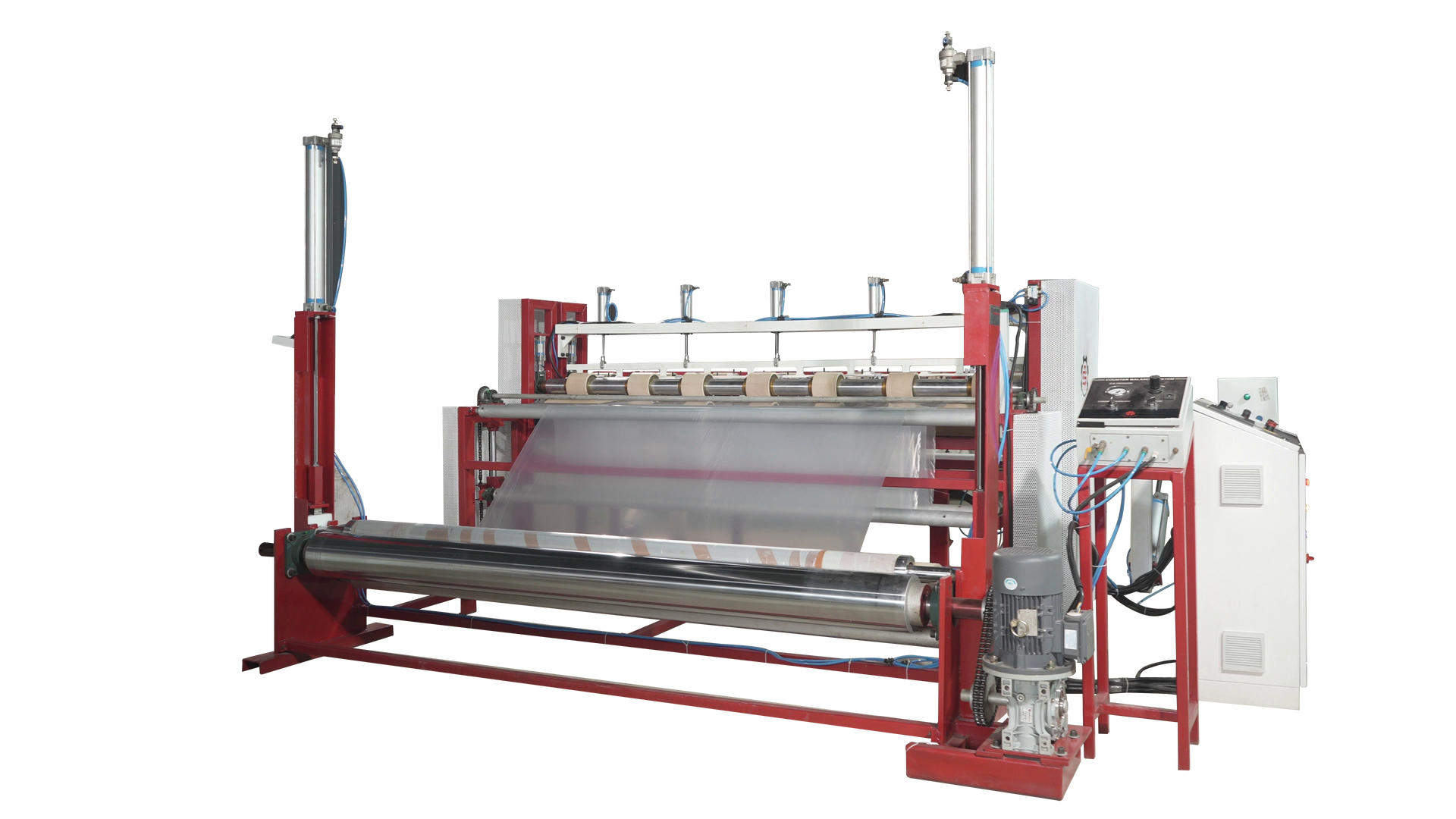

FABRIC CUTTING MACHINE

We manufacture Fabric cutting machines for FIBC jumbo bags and for woven sacks. The fabric cutting machine is ideal for fast and proficient cutting, better finishing, and helps save labor costs.

Fabric Cutting Machine for FIBC Jumbo Bags:

The FIBC fabric cutting machine makes fabric cutting easier and supports two types of cutting:

1. Heat cut: Heat-cut fabric cutting for precise production is the best choice.

2. Ultrasonic cut: Ultrasonic fabric cutting for food-grade production is the best choice.

LINER SEALING MACHINE

We manufacture a wide range of linear sealing machines to seal the liners using liner rolls and also to create different PE liners to insert into big bags. The different models we manufacture include:

- PE Bottle Shape Sealing Models

- PE Suspended Liner Sealing Models

- PE Aluminum Folio Sealing Models

- PE Gambo Liner Sealing Models

AUTOMATIC SPOUT & BAFFLE PUNCHING MACHINE (ROLL TO PIECE)

We are proud to unveil a breakthrough in FIBC / Jumbo Bag manufacturing – a newly designed, fully automatic Spout and Baffle Punching Machine, developed for unmatched precision and speed. This is the first-of-its-kind innovation in India, engineered and manufactured by Armstrong, the name synonymous with excellence in FIBC finishing machines.

Key Highlights:

2-in-1 Functionality: Combines spout punching and baffle punching in a single automated solution – saving time, space, and labor.

High Efficiency: Performs 7 baffle punches in a single cycle, delivering speed without compromising accuracy.

Robust Engineering: Built with a durable, industrial-grade design for long-term reliability and minimal maintenance.

Precision & Speed: Ensures clean, consistent, and accurate punching for every cycle, enhancing the quality of your bags.

Made in India, Made for the World: A proud innovation designed to elevate Indian manufacturing to global standards.

BAFFLE PUNCH MACHINE

We manufacture and export FIBC Baffle Punching Machine to make panels for jumbo bags. Baffle bags are specifically designed FIBC bags with four panels stitched onto their corners. Their unique build safeguards products from damage and the bags retain their cubical shape to allow easy stacking and transporting of goods.

The machine cuts the baffles in PP fabric pieces efficiently and quickly. The FIBC baffle punching machine supports capsule and oval-shaped punches with hot or cold cuts. The semi-automatic machine helps cut down the cost, save time, and thus, increase productivity.

BELT CUTTING MACHINE

Armstrong is one of the leading suppliers and exporters of finishing machinery and spares for the PP industry. The FIBC belt-cutting machines we manufacture help cut handles or loops for jumbo FIBC bags. We create handles or loops for FIBC bags in needle loom machines; they are then further processed in belt-cutting machines.

The significant benefit of the FIBC belt-cutting machine is that it eliminates waste by cutting the exact quantity for the short and long legs of the belt. The machine cuts 5-10 pieces at one time.

ELECTRICAL BALE PRESS MACHINE

ARMSTRONG Electric Bale Press Machine is typically a piece of equipment used for pressing and compacting large bags, often in industries like textiles, agriculture, or packaging. These machines are designed to handle heavy-duty, large-sized bags (commonly called jumbo bags or FIBC - Flexible Intermediate Bulk Containers) and apply pressure to either compress, form, or seal the bags during manufacturing or processing. This bale press is also used for small bags packing, especially when the bag quantity is less.

BALE PRESS MACHINE

We manufacture semi automatic and FIBC Jumbo hydraulic Bale Press machines for bailing of both HDPE Woven sacks and FIBC bags. The Bale Press machines help compress the bags into bales to consume less storage space. Thus, it helps in transporting bags with fewer costs and time.

BAG CLEANING MACHINE

We are the manufacturers and exporters of bag cleaning machines for efficiently cleaning FIBC bags from inside and outside. With pre-filtered air technology and the automated cleaning process of the bag-cleaning machine, we ensure to remove loose threads, foreign particles, or other elements from inside the bags.

The machine has a static charger, 2 HD cameras, and a LED display to clearly see inside the bags for proper cleaning. The programmable logic controller controls the entire operation.

FIBC / PP FABRIC REVERSING MACHINE

This machine is designed to reverse the bag or fabric, this is required majorly to do lamination in the inner side of the bag or fabric. The bag or fabric reversing operation is conventionally carried out manually using 4 operators. With our semi automatic bag reversing machine the same operation can be carried out using only 1 operator and with much higher efficiency.

LINER OPENER MACHINE

We manufacture liner opener machines to speed up inserting and sticking PE liners into PP FIBC bags. The Machine has pneumatic arms that provide proper opening and space between the PE liner and inner lines of the FIBC jumbo bag with no wrinkles. The liner is placed on the pneumatic arms, and the operator applies the glue. Once done, the FIBC bag is placed over the liner.

TESTING RIG MACHINE

We are the manufacturer and supplier of bag testing rigs that help test the quality of produced bags. The machine also performs top lift tests of FIBC with single point & multiple point suspensions. The rig test machine has four cameras, a digital dashboard, and a sensor system. The machine measures the strength of the fabric and the stitches by loading them onto the metal hooks and aligned correctly. The sensor system applies a certain amount of weight and pressure to test the strength.

Armstrong FIBC Bag Testing Machine can perform the following tests:

- Burst Testing

- Cycle Testing

- Hold Testing

- Peak Testing.

STRAPEX MACHINE

The Strapex Handle Wrapping Machine is designed to cover the handles of big bags/ FIBCs with fabric. The wrapping fabric around the handles makes them strong for lifting and easy to transport. The machine is ideal for 1 Loop or 2 Loops Big Bag ( Jumbo Bag / Bulk Bag / Container Bag / FIBC ).

Strapex is automatic, compact, and operates easily. The features of the machine like inverter-controlled sewing machine movements and timer-controlled operations help save labor.

The video shows the big bag Strapex machine with the process for material production.

First, the wrapping fabric is placed on the machine. After that, the fabric is tightly wrapped around the handle with a pneumatic system. In the next step, the moveable sewing machine and knife start stitching, and the knife trim the fabric simultaneously. Once the sewing is done, the thread is cut by a cam system 4-5 cm away from the fabric. Once the process is over, the sewing machine and the knife return to their home position.

Features

- Automatic handle wrapping fabric feeding and pulling

- Upper and lower feed, 1 needle 2 thread, chain stitch sewing head

- Automatic thread chain cutting

BAG ROLLING MACHINE

Armstrong is the one-stop solution provider of finishing machinery for the PPE industry. We are the proud first manufacturers of the FIBC bag rolling machine in India. The machine makes it easier to roll one-loop and two-loop bags for testing and automatic filling lines. The FIBC bag rolling machine packs the bags tightly to avoid wrinkles during transportation.

The Bag Rolling machines we create are ideal to create single loop and double loop bags to transport bulk loads.

As a leading manufacturer and exporter of industrial machinery, we never compromise on quality. All the bags we create undergo rigorous quality testing for fabric quality and strength. We ensure the bags quality complies with international packaging goods standards.

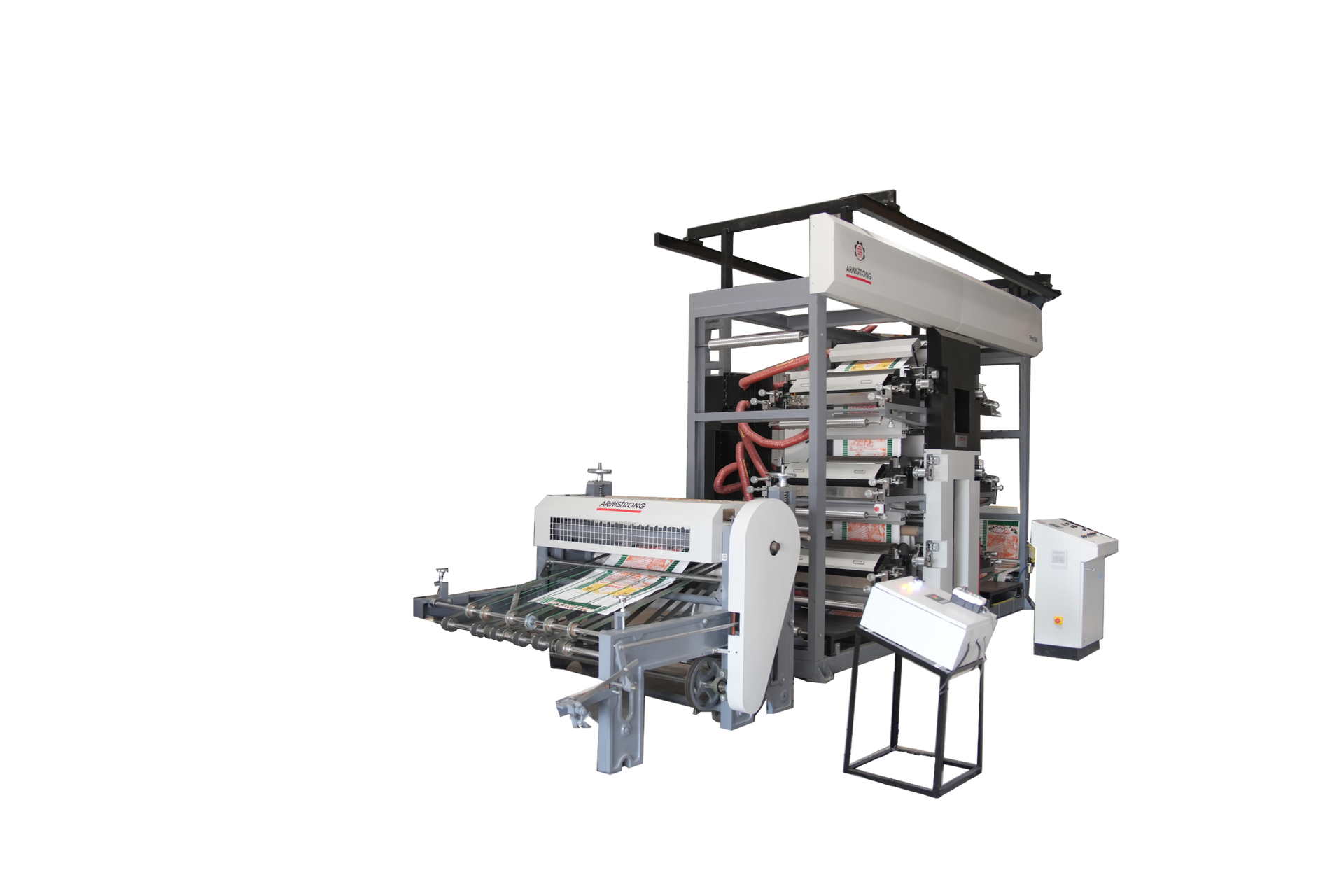

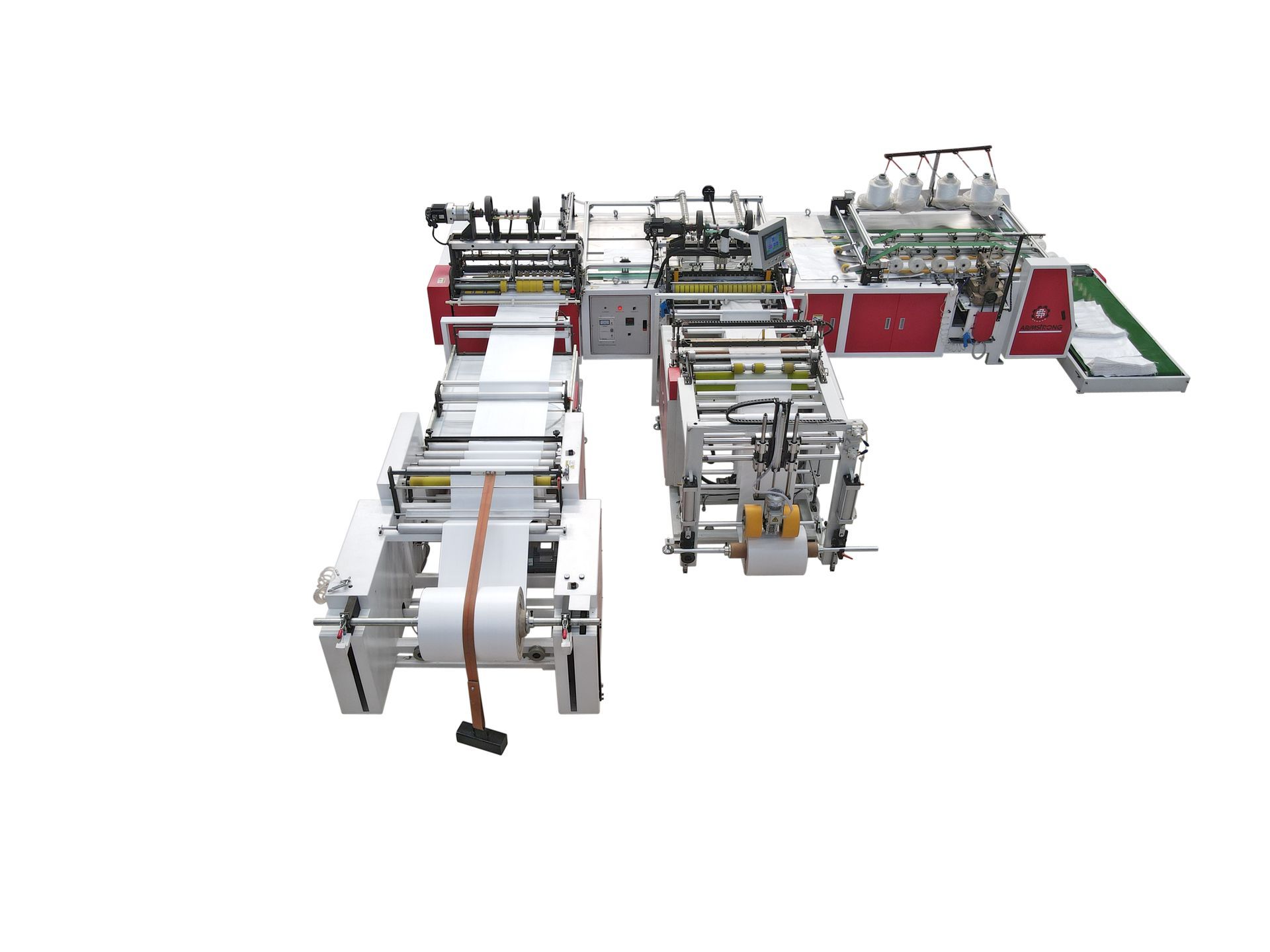

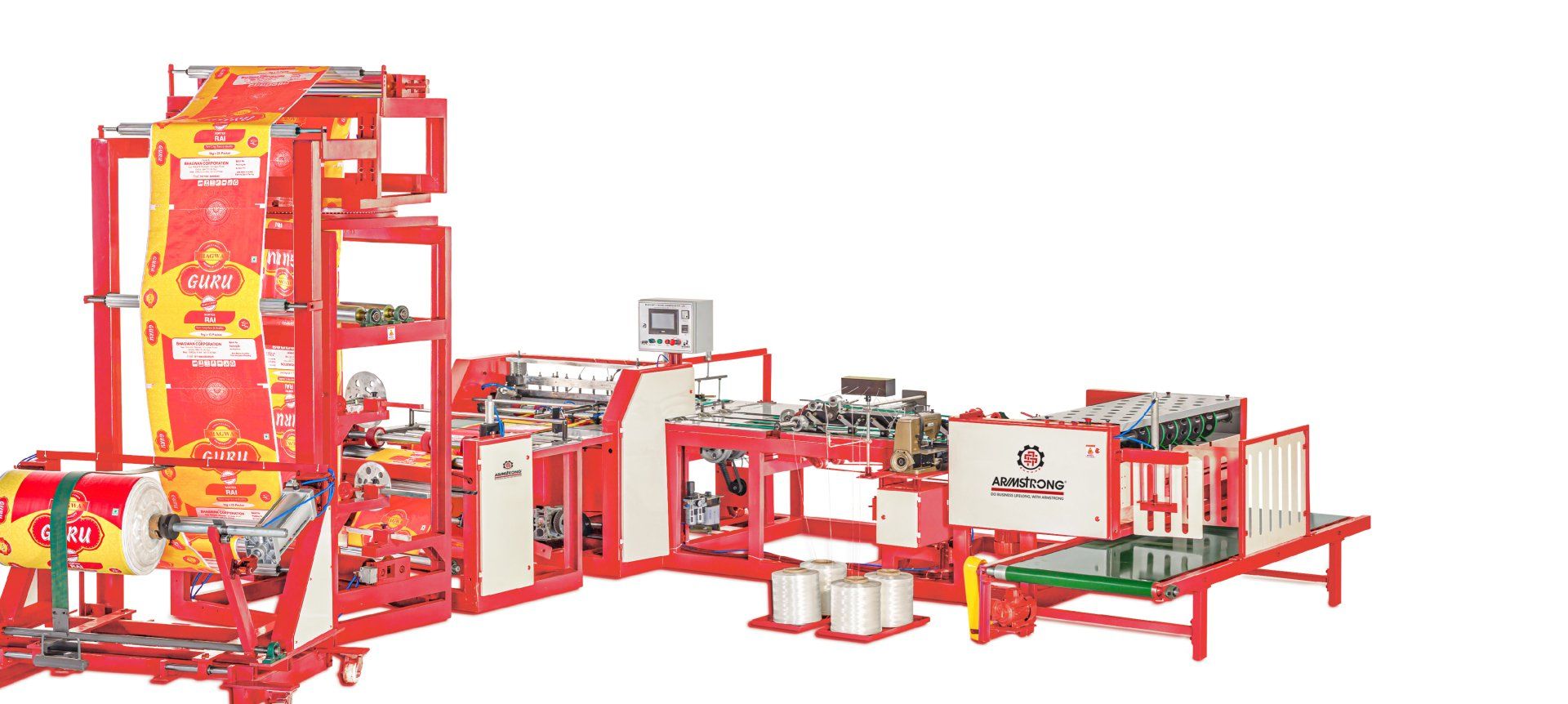

BCS MACHINE

We are the manufacturer and exporter of automatic woven bag cutting & stitching machines for PP/HDPE/BOPP bags. Our automatic cutting and stitching machine has a servo motor for precise cutting length. The machine has a high-speed conversion line for cross-cutting, bottom folding, sewing, and stacking bags and is designed for fabric widths up to 300 – 800 mm and speeds up to 30 -45 bags/min.

ARMSTRONG STITCHING

We are the manufacturer and exporter of automatic woven bag cutting & stitching machines for PP/HDPE/BOPP bags. Our automatic cutting and stitching machine has a servo motor for precise cutting length. The machine has a high-speed conversion line for cross-cutting, bottom folding, sewing, and stacking bags and is designed for fabric widths up to 300 – 800 mm and speeds up to 30 -45 bags/min.

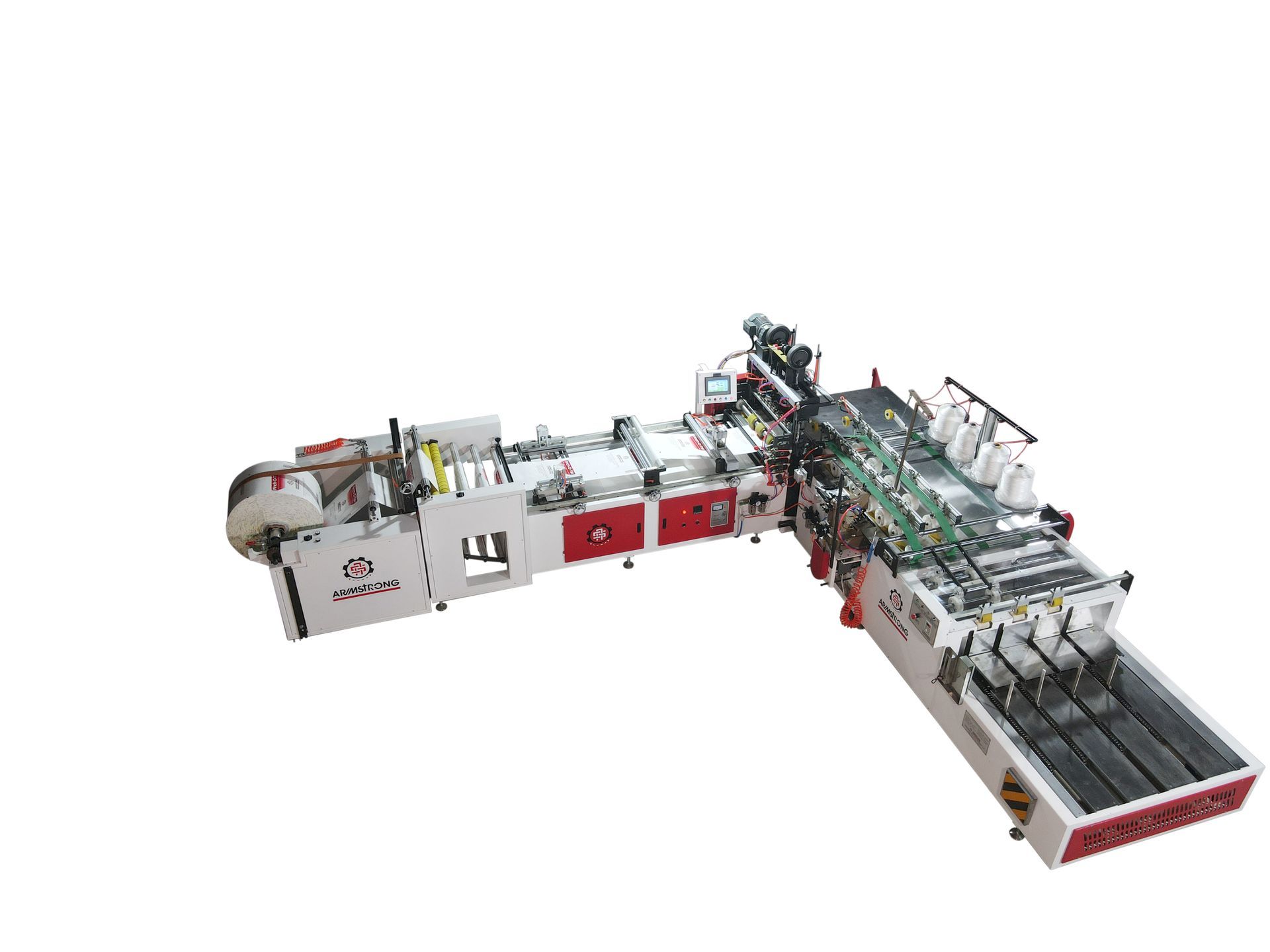

GUSSET BCS MACHINE

Armstrong is one of the finest manufacturers and exporters of industrial machinery and spares. We provide an efficient auto woven sack cutting machine with a unique gusset device for extra accuracy and finesse.

The machine is ideal for manufacturing bi-axially oriented polypropylene (BOPP) and laminated bags. The machine has a unique twist gusset device that ensures secured cutting and sealing of bags. Secondly, the operating system makes it easy to use and helps avoid errors. The machine has the following features:

- Programmable logic controller with a touch screen.

- A data backup system.

- The auto fabric roll lifting device with a power pack system.The I-Mark Proxy assures accurate cutting and sealing on the printed laminated bags.

- A perforation roller efficiently cuts woven sacks.

- Zigzag & plane heat cutters for unlaminated fabric.

- Rod-less cold cutter for laminated fabric

- Single & double folding device.

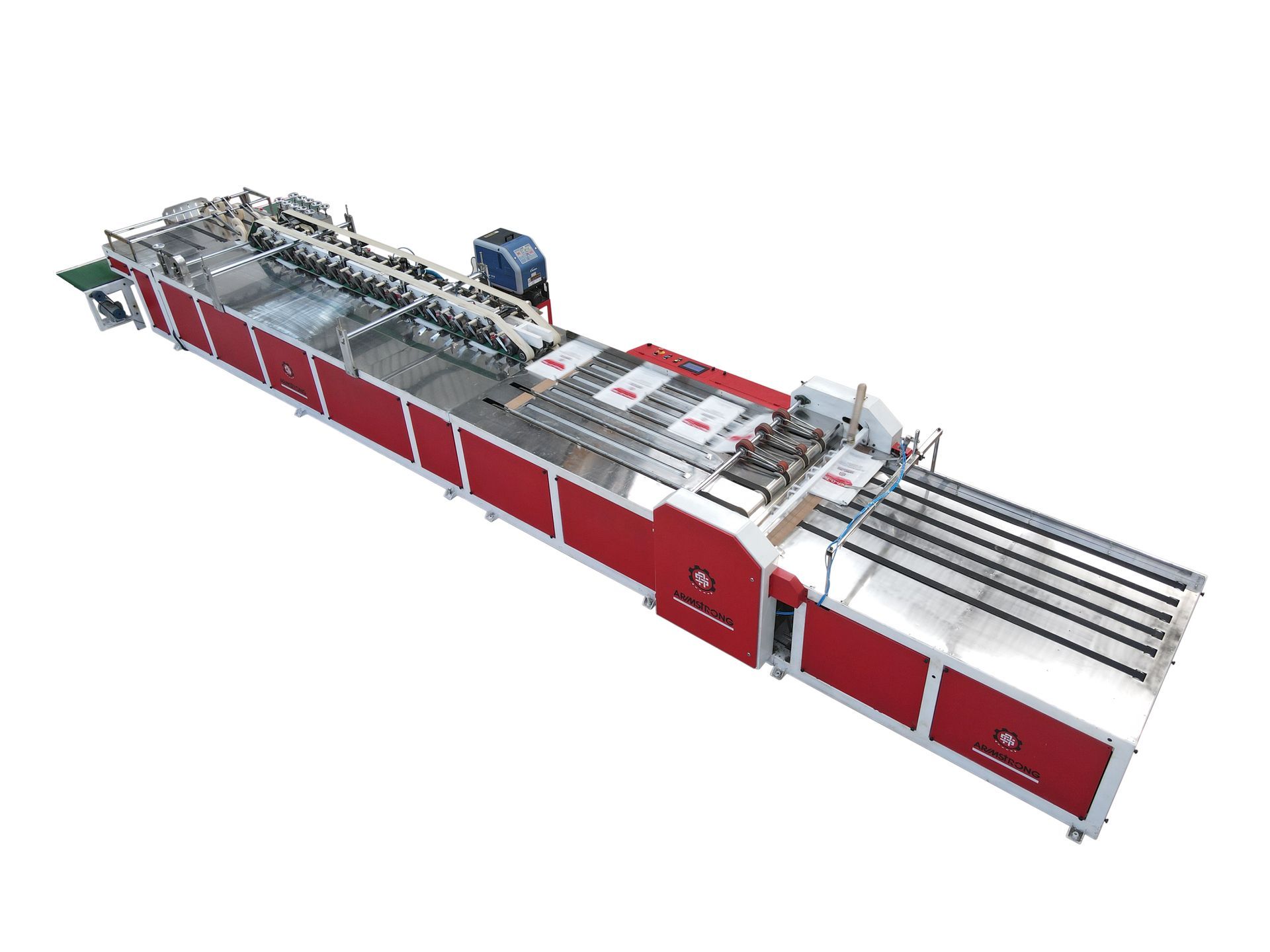

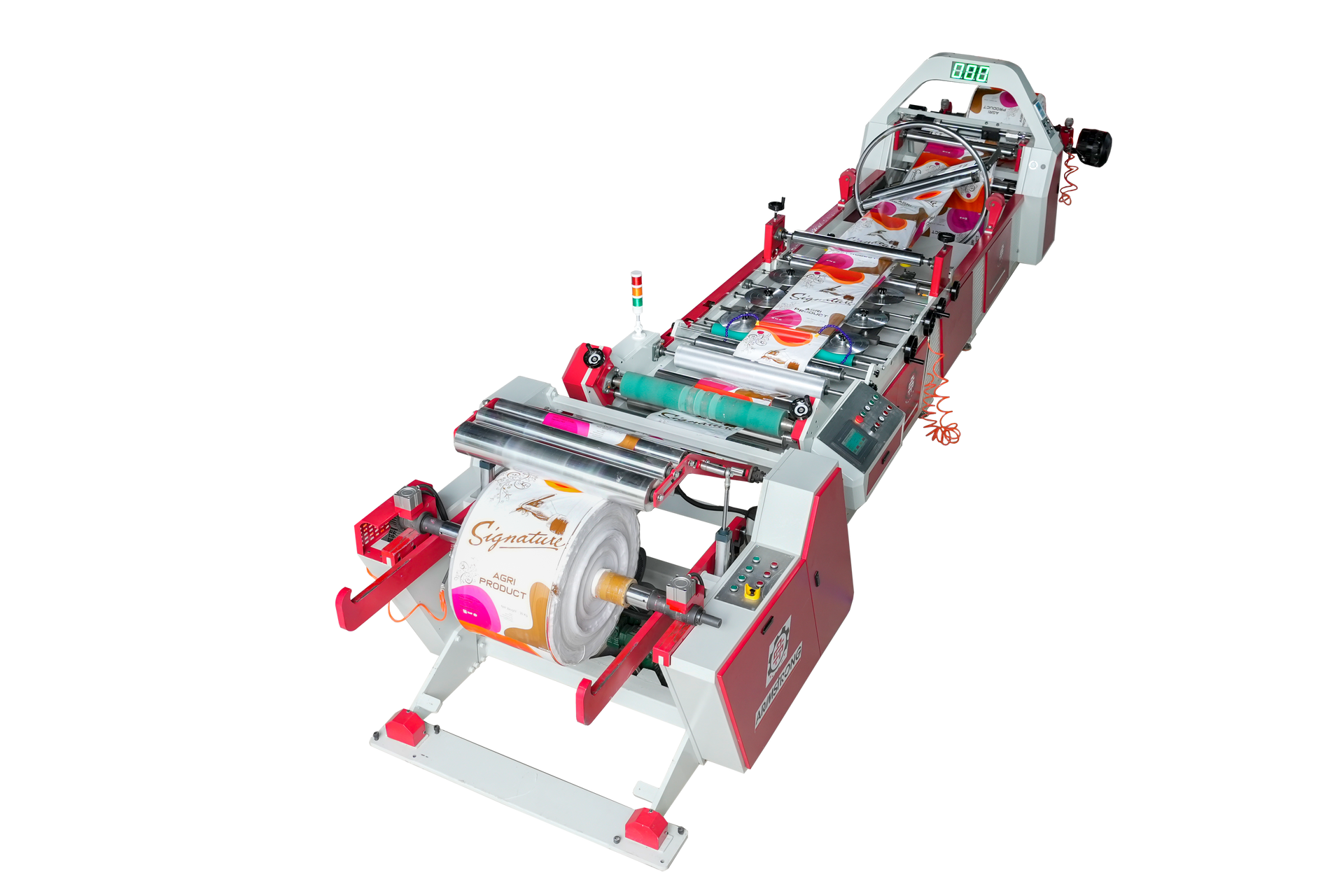

NEWLONG BAG SEWING MACHINE

Armstrong is one of the finest manufacturers and exporters of industrial machinery and spares. We provide an efficient auto woven sack cutting machine with a unique gusset device for extra accuracy and finesse.

The machine is ideal for manufacturing bi-axially oriented polypropylene (BOPP) and laminated bags. The machine has a unique twist gusset device that ensures secured cutting and sealing of bags. Secondly, the operating system makes it easy to use and helps avoid errors. The machine has the following features:

- Programmable logic controller with a touch screen.

- A data backup system.

- The auto fabric roll lifting device with a power pack system.The I-Mark Proxy assures accurate cutting and sealing on the printed laminated bags.

- A perforation roller efficiently cuts woven sacks.

- Zigzag & plane heat cutters for unlaminated fabric.

- Rod-less cold cutter for laminated fabric

- Single & double folding device.