The best machines for designing Polypropylene bags

Polypropylene is one of the most commonly used materials for packaging. The ideal qualities of the material make it the best choice for the packaging industry. In this post, we’ll take you through several reasons that make polypropylene bags the ideal choice for packaging.

Top benefits of using Polypropylene bags for packaging

The features of polypropylene that are put into use in the packaging industry include the following:

- Water resistance

Polypropylene is highly resistant to water, making it ideal for packaging products that need to be protected from moisture damage. It is used in the transport of moisture-prone materials like wood. The hydrophobic nature of polypropylene provides a protective layer around the material being transported, keeping it safe even when exposed to damp environments.

- Durability

Polypropylene is a highly durable material that can withstand wear and tear over time. It is resistant to abrasion and can withstand considerable amounts of friction which is common in the case of transport. This makes it ideal for packaging bags that need to withstand rough handling during transportation and storage. It is also resistant to impacts like a blow which protects the transported material from cracking up during the transport process.

- Lightweight

Polypropylene is a lightweight material which means it hardly adds to the total weight when packed. It is easy to handle and is compact, which is a great choice in comparison to the bulkier counterparts like thermocol or cardboard boxes. This makes it ideal for packaging bags that need to be transported over long distances.

- Flexibility

Polypropylene is a flexible material that can be easily moulded into different shapes and sizes. The flexibility of polypropylene makes it ideal for use in applications where products need to be able to bend or deform without breaking.

For example, packaging bags made from polypropylene can be easily folded, twisted, and stretched to accommodate a wide range of products. This feature of polypropylene allows manufacturers to create packaging bags that can accommodate a wide range of products.

Polypropylene also has good shape memory meaning it not only moulds to the required shape but also stays intact and can also come back to its original shape when required.

- Cost-effectiveness

Polypropylene is a relatively inexpensive material, making it an attractive option for packaging bags that need to be produced in large quantities. Since the transport material is required in large quantities, polypropylene with the ideal features becomes a cost-efficient option.

Different types of machines used in producing polypropylene woven bags

- BCS machine or Bag cutting and stitching machine

A BCS machine is used to create polypropylene bags from a roll of flat material. This pp-woven bag-making machine cuts and seals the material to create bags of different sizes and shapes. The BCS machine by Armstrong is of utmost precision and comes with a good power motor. The cutting speed can be adjusted based on the requirement, and the number of bags that can be produced at a time can vary from anything from 30-45 bags per minute.

- Extrusion machine

This is the most common type of machine used for making polypropylene bags. It involves melting polypropylene pellets and extruding them through a die to create a flat sheet of material. The sheet is then cut and folded into the desired shape to create the bag.

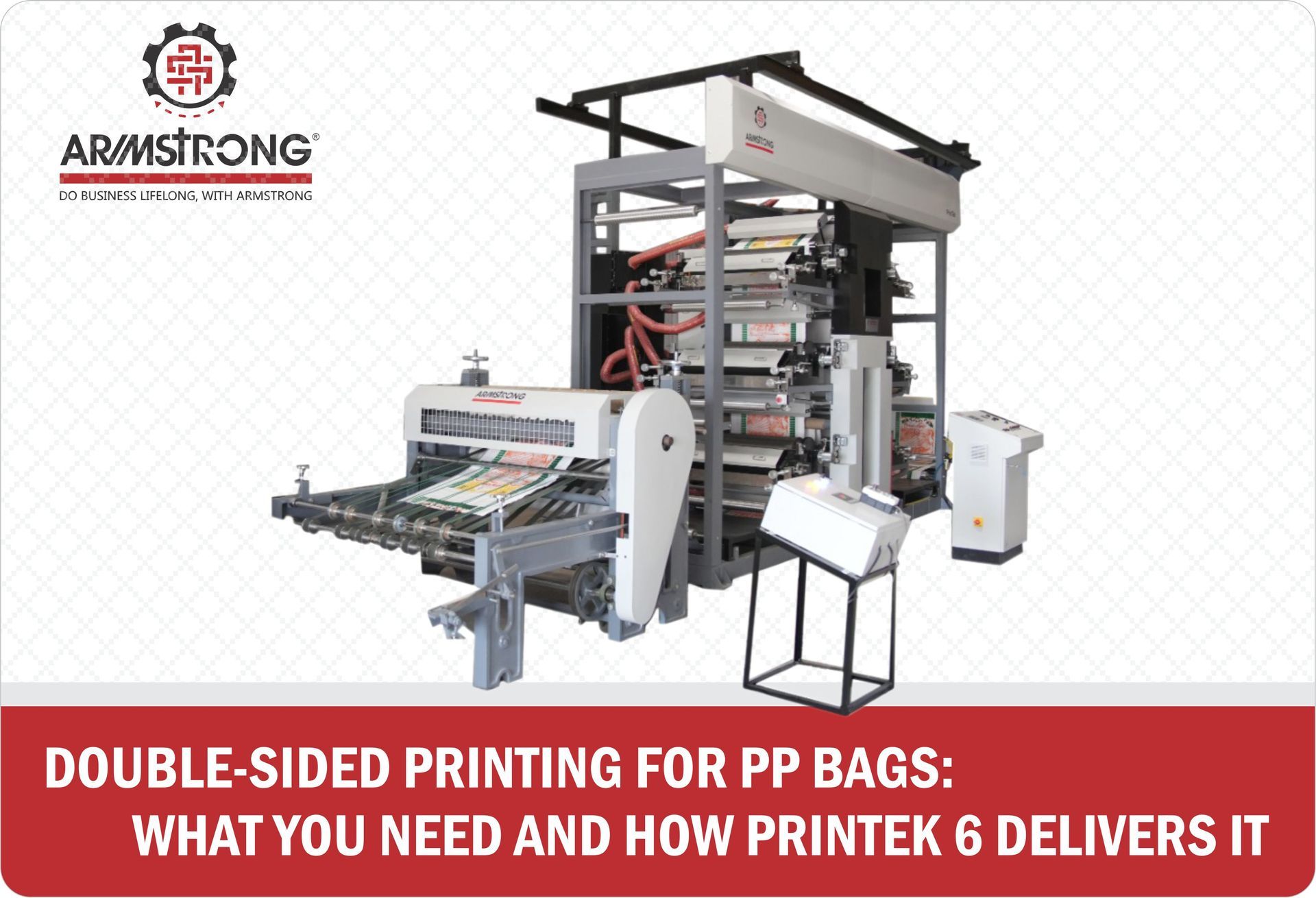

- Flexographic printing machine

The flexographic printing machine is used to print designs or logos onto polypropylene bags. It uses flexible printing plates and a roll of polypropylene material to print high-quality images onto the bags.

- Circular weaving machine

A circular weaving machine is used to create woven polypropylene bags, which are known for their strength and durability. The machine weaves polypropylene tapes into a tubular shape, which is then cut and stitched to create the bag.

The best machine for making polypropylene bags will depend on factors such as the desired bag size, production volume, and the specific requirements of the production process. The BCS machine by Armstrong has several compatible features to produce bulk quantities of polypropylene bags.